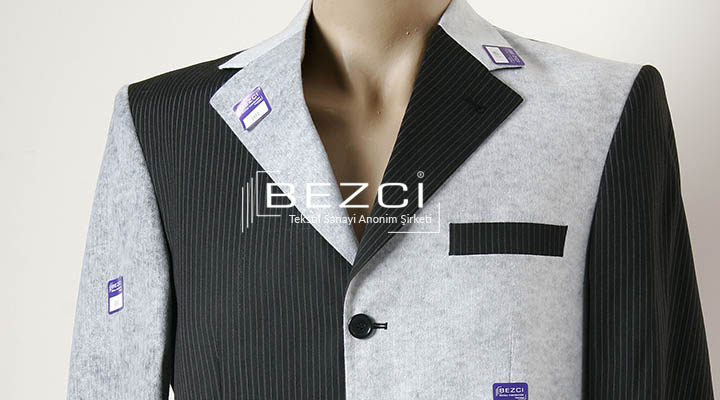

Correspondence of the interlining to the correct type of the fabric is very vital for the garment producers. For an advice; the interlining should be in a harmony with the fabric such a way that the fabric is gained a weight without loosing its character.

We recommend you to consider choosing the appropriate interlining according to:

• Characteristics of the fabric depending on colour and model,

• The appropriate weight that is required for the fabric,

• The area that the interlining will be used,

• Cleaning conditions, and ironing instructions.

We also recommend that fusing trials and subsequent care treatments should be carried out before the production commences.

Nonwoven Interlinings have divided into three diffrent systems depending on the type they are coated.

SCATTER SYSTEM INTERLININGS

In Scatter Coating system, the Nonwoven is more or less equally scattered with adhesive melting powder. The heaviness of Scatter System Interlinings varies from 28 gr/sqm to 80 gr/sqm, having the width alternatives of 70 cms and 90 cms. The available colours are White and Charcoal. Scatter System Interlinings are generally coated with polyethylene. And leather interlining have the possibilty of coating with EVA. This group also includes Top Fuse for fusing to collars on leisure and semi-interlinings are avaible lightweight fusible for small area fusing to blouses. The heavier scatter Interlinings, except Leather Interlining, can be fused at 140ºC-150 ºC, between 12-15 seconds. Scatter Interlinings are good at 40 ºC of washing unfortunately, can be fused at 90-110 ºC, between 10 to 12 seconds.POWDER POINT SYSTEM INTERLININGS

In Powder Point Coating System, the substrate is equally sprinkled with powder out of roller, which is sintered by heating. The heaviness of Powder Point Interlinings varies from 28 gr/sqm to 80 gr/sqm, having the width 90 cms. The available colours are White and Charcoal, Powder Point Interlinings have the possibility of coating with Polyamide Powder. The Lighter Powder Point Interlinings can be either used to small areas where volume is needed or ideal for fusing to difficult fabrics, Heavier Powder Point Interlinings have a higher base weight which provide an additional volume on the front application of jackets, over-coats, suits, trousers, and can be used in belts. Powder Point Interlinings can be fused between 145 ºC-155 ºC degree of temperature between 10 to 12 seconds, 40 ºC degree of washing is recommended. The Powder Point Interlinings are resistant to dry cleaning and good for the stream.PASTE POINT SYSTEM INTERLININGS

In Paste Point Coating System, the Nonwovens are printed with a regular dot pattern in rotating screen-printing machine. The heaviness of Paste Point varies from 25 gr/sqm to 70 gr/sqm, with having the width of 90 cms. The available colours are White and Charcoal. Paste Point System Interlinings usually preferred where support is necassary for light and medium weight outer fabrics. The Paste Point Interlinings may be applied on small or/and large areas for ladies’ wear-dresses, blouses or wear coats, jackets and and coated with PA/PES mixture of base Nonwoven coated with PA Paste, this product adds hardly any extra weight to light weight fabrics, thereby maintaining the character of the fabric perfectly. Paste Point Interlinings need 145 ºC-155 ºC degree of temperature and 10 to 12 seconds to be fused. 40 ºC of wash is recommended; they are resistant to dry cleaning and good for steam like other Nonwoven Interlinings.STITCHED NONWOVEN INTERLININGS

All Nonwoven interlinings has a limited flexibility and strength. Nonwoven Interlinings have an advantage of having lighter weights, smooth surface and softer touch than Woven Interlinings However; in some circumstances, Nonwoven Interlinings need to have light weight and resistantancy. This requirement happens when it is needed to reduce the flexibility of elastic fabrics in one way. In order to reduce the flexibility of the fabric, reinfocement is made by stitching Thermobond Nonwovens by a special knitting machine.Nonwoven Interlinings are knitted by a special knitting machine in certain distances with polyester yarn. Thus; Stitched Nonwoven Interlining reflects the same usage characteristics of Nonwoven and Woven Interlinings as it appears in between them. Stiched Nonwoven Interlinings are coated by Polyamide or Polyester paste dots.

SPECIAL APPLICATIONS

There are special coating types rather than Standard ones. These are;1- Nonwoven paste dot Interlinings that are sticked in lower temperatures. These products are used in leather garments.

2- Special Woven and Nonwoven Interlinings that are used to stick on siliconised and slippy finished fabrics.

3- Interlinings that have different sticking temperatures and washing properties.